Reducing Environmental Impact to Achieve a Sustainable World.

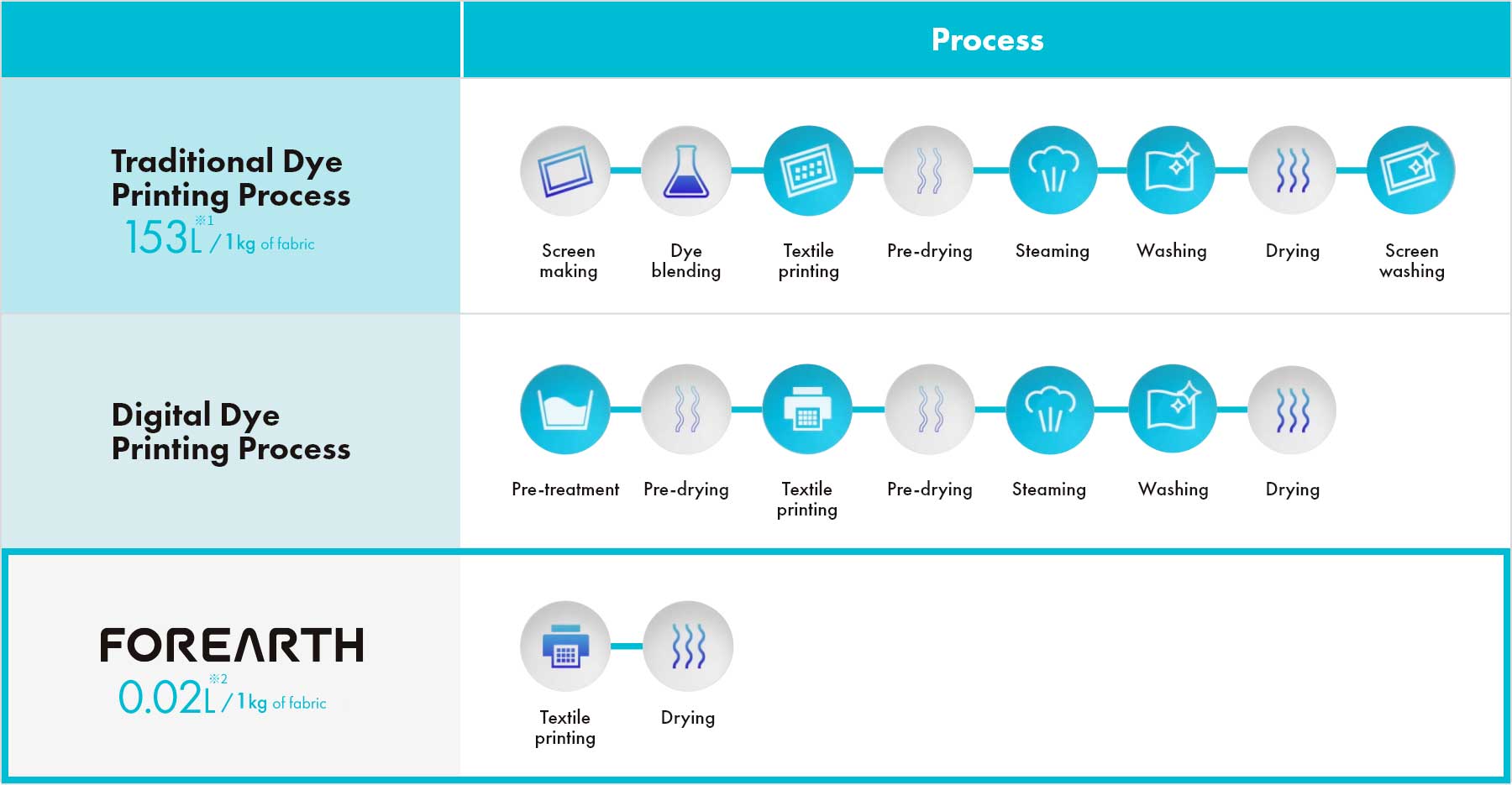

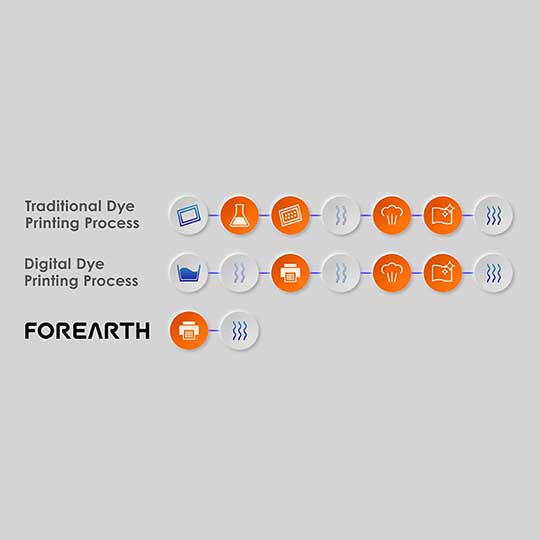

Traditional dye printing, which has four processes requiring water, uses 153L* of water per 1kg of fabric while FOREARTH has a simple two-step printing and drying process.

No water is used in the printing process based on the concept of “WATER FREE”. Kyocera focuses on reducing water usage not only for the printing process but also for the maintenance process.

FOREARTH also recycles cleaning water used for the conveyor belt with filters resulting in water consumption per 1kg of fabric reduced to 0.02L**.

FOREARTH contributes to the realization of sustainable textile printing.

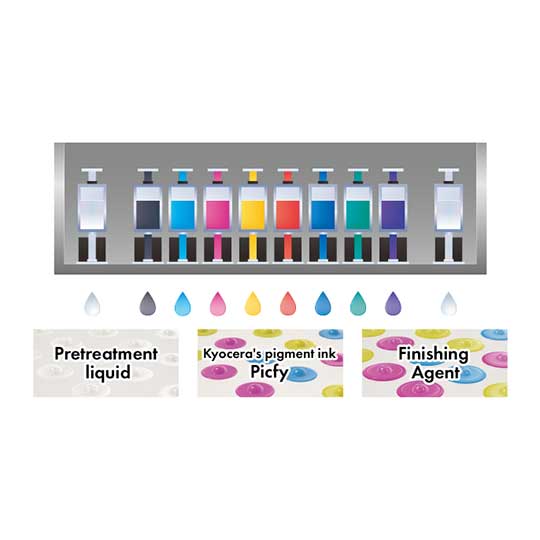

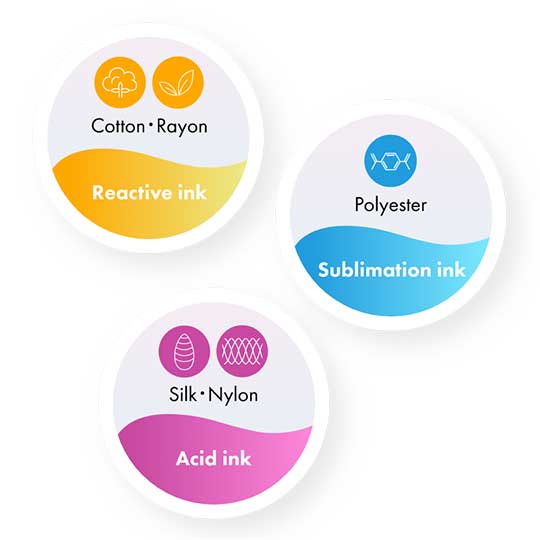

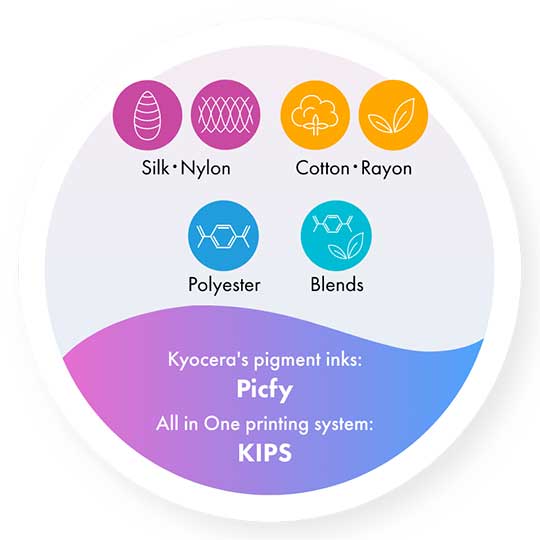

FOREARTH uses Kyocera’s proprietary pigment ink, pretreatment liquid and finishing agent to realize high quality printing on a wide range of fabrics, including cotton, silk, polyester, nylon and blended fabrics.

In addition, by discharging the pretreatment liquid, pigment ink, and finishing agent in a continuous cycle, the product maximizes the performance of each element and maintains softness of the fabric.

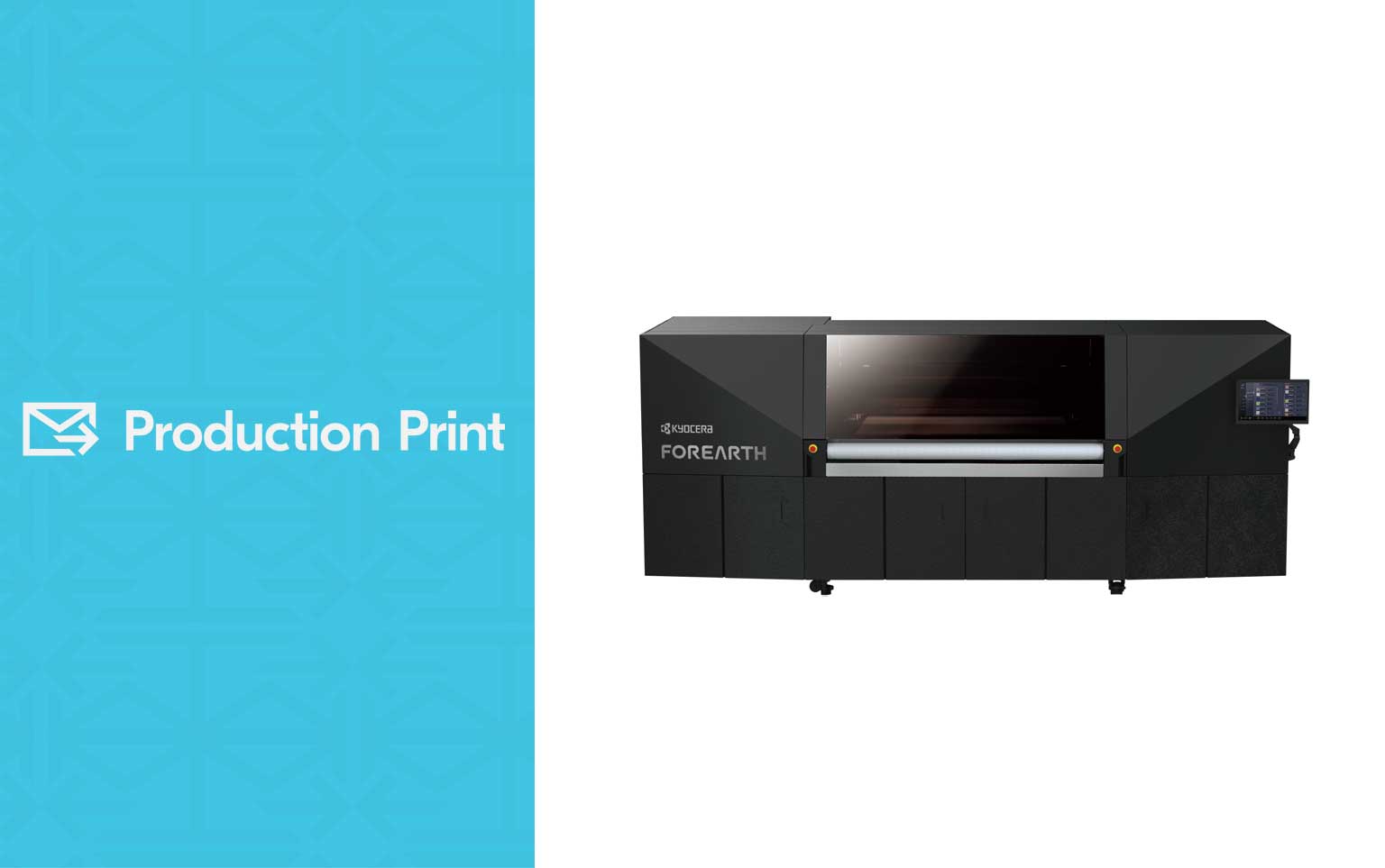

This digital texile printer is free from the limitation of screen printing. As a result, FOREARTH achieves vibrant and high-definition printing with a flexibility in design size.

It can be used across a broad range of categories- from women’s fashion to sports and kids’ wear and home textiles. FOREARTH expands creative possibilities and helps create new value in the textile and apparel industry.

FOREARTH’s system has only two steps – printing and drying.

Because it does not require separate facilities for pre- and post-treatment processes needed in conventional textile printing, it enables to drastically shorten the numbers of processes from design to production.

With FOREARTH, it is possible to print only the amount needed and respond to short lead time requests and avoid a surplus in inventory.

FOREARTH uses very little water for printing so that production can be set up almost anywhere, including on-shore, near-shore, or more suitable areas close to consumers. FOREARTH contributes to the reduction of lead time and logistics costs.